Others Yarn Faults or Defects?

Others Yarn Faults or Defects?

Answer:

These faults are mainly categorized as below:1. Frequently occurring faults (analyzed by uster evenness tester)

2. Seldom occurring faults (scanned by uster classimat tester)

Frequently occurring faults:

1. Thick places

2. Thin places

3. Neps

Thin places and thick places are produced due to drafting irregularities and neps are generated due to immature fibers in the raw material.

Seldom occurring faults:

1. Slobs

2. Spun in fly

3. Long thin places

These faults are also known as objectionable faults.

Why these yarn faults to be avoided:

causes break during post spinning operations.

Detract aesthetic appeal of the fabric, if allowed to pass.

Objectionable yarn faults can be categorized in three groups:

1. Faults due to raw material

2. Faults due to piecing

3. Faults due to spinning machine

Faults due to the raw material: the number of objectionable faults due to raw material varies from 16% to 30% with different yarns.

Faults due to piecing: the number of objectionable faults due to piecing varies from 9% to 16% of the total objectionable faults.

Faults due to the spinning machine: the spinning frame (r/f) is responsible for about 50% to 60% of the total objectionable yarn faults.

Defects present in yarn can be classified into five categories:

1) count variation: variation in diameter along the length of yarn beyond the acceptable range.

2) unevenness or irregularity: it is mass variation per unit length (cm). This fault is expressed as u% or cv% and evenness tester is used to measure it.

3) frequently occurring faults: these are the faults that occur in the range of the 10 to 5000 times per 1000 m of yarn. Yarns spun from staple fibers contain imperfections, which can be subdivided into three groups:

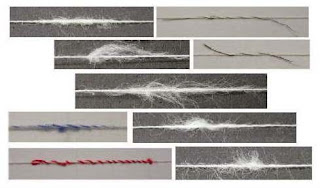

Thin places: cross-sectional size -30% to -60% of normal yarn with fault length of 4 to 25 mm.

Thick places: cross-sectional size +30% to +100% of normal yarn with fault length of 4 to 25 mm.

Neps: cross-sectional size +140% to +400% of normal yarn with fault length of 1 mm. Neps are defined as small tight balls of entangled fibres on linear textile strands.

4) seldom occurring faults: these are the thick and thin places in the yarn which occur so seldom that for their determination at least 100,000 m of yarn must be tested. This faults may be classified into the following classes:

a. Short thick places: 1 to 8 cm and above +100%

b. Long thick places: above 8 cm and above +45%

c. Long thin places: above 8 cm and less than -30%

5) periodic faults: if any fault repeats after a certain length/time then the fault is called the periodic or systematic fault.

6) hairiness: this is the measure for the protruding fibers from the yarn body.

7) lot mixing: sometimes yarn lot can be mixed at the stages of the spinning process as well as in the preparatory section of weaving/knitting mill. This type of mixing causes the severe problem in subsequent processes.

Objectionable yarn faults can be categorized in three groups:

1. Faults due to raw material

2. Faults due to piecing

3. Faults due to spinning machine

Faults due to the raw material: the number of objectionable faults due to raw material varies from 16% to 30% with different yarns.

Faults due to piecing: the number of objectionable faults due to piecing varies from 9% to 16% of the total objectionable faults.

Faults due to the spinning machine: the spinning frame (r/f) is responsible for about 50% to 60% of the total objectionable yarn faults.

Defects present in yarn can be classified into five categories:

1) count variation: variation in diameter along the length of yarn beyond the acceptable range.

2) unevenness or irregularity: it is mass variation per unit length (cm). This fault is expressed as u% or cv% and evenness tester is used to measure it.

3) frequently occurring faults: these are the faults that occur in the range of the 10 to 5000 times per 1000 m of yarn. Yarns spun from staple fibers contain imperfections, which can be subdivided into three groups:

Thin places: cross-sectional size -30% to -60% of normal yarn with fault length of 4 to 25 mm.

Thick places: cross-sectional size +30% to +100% of normal yarn with fault length of 4 to 25 mm.

Neps: cross-sectional size +140% to +400% of normal yarn with fault length of 1 mm. Neps are defined as small tight balls of entangled fibres on linear textile strands.

4) seldom occurring faults: these are the thick and thin places in the yarn which occur so seldom that for their determination at least 100,000 m of yarn must be tested. This faults may be classified into the following classes:

a. Short thick places: 1 to 8 cm and above +100%

b. Long thick places: above 8 cm and above +45%

c. Long thin places: above 8 cm and less than -30%

5) periodic faults: if any fault repeats after a certain length/time then the fault is called the periodic or systematic fault.

6) hairiness: this is the measure for the protruding fibers from the yarn body.

7) lot mixing: sometimes yarn lot can be mixed at the stages of the spinning process as well as in the preparatory section of weaving/knitting mill. This type of mixing causes the severe problem in subsequent processes.

No comments