Weaving Preparation of Woven Fabric?

Weaving Preparation of Woven Fabric?

Answer:

Weaving Preparation:

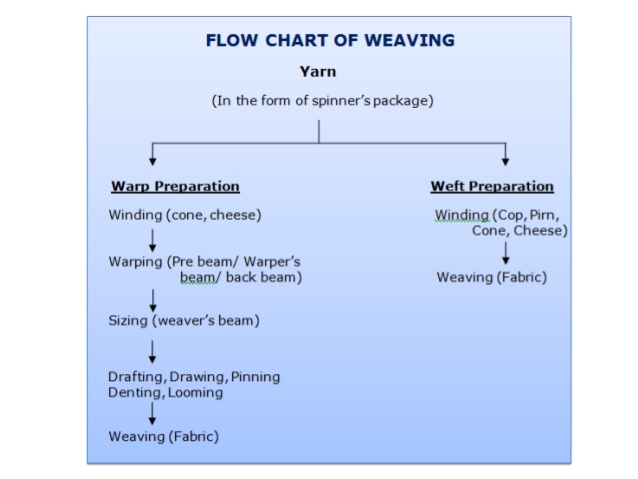

Weaving Preparation: Yarn is the basic building block in weaving. Therefore, after yarn manufacturing, the next successive steps would be to weave the yarn into a fabric. However, in practice, the condition of yarn produced on the spinning machine is not always good enough to be used directly for fabric formation. Package size, yarn surface characteristics, and other factors make it necessary for both weft yarn and warp yarn to be further processed for efficient fabric formation. These preparatory processes are called weaving preparation.Warp and weft yarns are subjected to different conditions and requirements during weaving, Therefore, the preparation of warp and weft yarns is different. Warp yarn is subjected to higher stresses which require extra preparation. The weft yarns are not subjected to the same type of stresses as the warp yarns and thus are easily prepared for the weaving process. Depending on the spinning method, the weft yarns may not be prepared at all, but rather taken straight off the spinning process and transported to the weaving process. This is the case with open-end (rotor), air-jet and friction spinning systems which provide a large single-end package suitable for insertion during weaving. However, ring spun yarns need to go through a winding process for several reasons that are explained below, The process used to prepare yams for weaving depends on yarn type as well Winding is the major preparation process for weft yarn. Warp preparation includes winding, warping, sizing and drawing-in or tying in Spun yarn quality characteristics that are most important for good weaving performance include short and long-term weight uniformity, imperfections, tensile properties, and hairiness. It should be noted that variation in a property is almost always more important than the average value of that property. Regardless of the processes employed, the second concept of quality has to be embraced. Not only must the quality of the yarn itself be maintained and enhanced, but also the quality of yarn packages is extremely important to further processing. The value of repair a yarn failure is much less if it happens before the weaving method. In a yarn failure during weaving also increases the chances for off quality fabric. Many if not most of the standard problems encountered throughout fabric forming are directly relating to mistakes created throughout yarn producing or yam preparation for weaving. Since winding is common for each pick and warp preparation, it'll be mentioned initially for each yarn systems. The weaving method is especially abusive to lengthwise yarns in a woven fabric, therefore, the technology encompassing the preparation of warp yarn for weaving is given special attention.

Weft Preparation:

Weft preparations are very short stages and it's only for looms. That means that for brand new weaving machines there's no need for any kind of preparation, the yarn packages are placed on the weft insertion creel directly as they're.For looms, the yarns have to be compelled to be converted from packages to a spool or a quill, on that the weft yarn is wound. This quill is inserted in a shuttle by that the weft is spread across the fabric. \

Warp preparation:

This stage is to organize the warp yarns for the weaving machines and it consists of, warping (direct and indirect), sizing (or Slashing) and so tying in or Drawing in.In this part, part I the introduction, we'll introduce an easy definition to every stage with an easy clarification. Parts II to V can deal very well with every stage on an individual basis. Part II: Direct warp, part III: Indirect warp, part IV: slashing and part V: tying in and Drawing in. Part II: is below construction and hopefully are uploaded in two weeks times.

No comments